joejoe123

Nouveau

bonjour a tous

j'ai acheté

Voila

http://www.aliexpress.com/item/CNC-kit-3Axis-Nema-34-Stepper-Motor-892OZ-In-85BYGH450D-007B-dual-shaft-Driver-DQ860MA-Power/1359103212.html

[highlight=#ffff80]et je si pas comment le câble , s'il te plait je voudrais comment le câblage (une schémas ) et la configuration de mach3[/highlight]

3 PCS Nema 34 Stepper Motor with 892oz-in (6.3N.m for bipolar connection)holding torque,dual shaft

3 PCS Stepper Motor Driver DQ860MA,24-80VDC,7.8A Peak Current,256 Microstep replacing MD882,

1 PCS 350W, 48VDC,7.3A, Power Supply.

1, Stepper Motor

Technical Specifications

Part No.: 85BYGH450D-007B (Dual Shaft)

Frame Size: NEMA34

Step Angle: 1.8 degree

Voltage: 6.4V

Current: 2.0A/phase

Resistance: 3.2 Ohm/phase

Inductance: 15 mH/phase

Holding torque: 6.16N.m 880oz-in (with Bipolar Connecting)

Rotor inertia: 3600g-cm2

Number of wire leads: 8

Weight: 3 kg

Length: 94mm

2, Stepper Motor Driver DQ860MA

Introduction:

DQ860MA is a type of two-phase hybrid stepping motor driver, The drive voltage of which is from 24VDC to 80VDC. It is designed for use with 2-phase hybrid stepper motor of all kinds with 57mm to 86mm outside diameter and less than 7.8A phase current. This circuit that it adopts is smiliar to the circuit of servo control which enables the motor run smoothly almost without noise and vibration. Hording torque when DQ860MA run under high speed is also significantly higher than the other two-phase driver, what’s more, the positioning accuracy is also higher. It is widely used in middle and big size numerical control devices such as curving machine, CNC machine, and computer embroider machine, packing machines and so on.

Features:

High performance, low price

Average current control, 2-phase sinusoidal output current drive

Supply voltage from 24VDC to 80VDC

Opto-isolated signal I/O

Overvoltage, under voltage, overcorrect, phase short circuit protection

15 channels subdivision and automatic idle-current reduction

8 channels output phase current setting

Offline command input terminal

Motor torque is related with speed, but not related with step/revolution

High start speed

High hording torque under high speed

3, Power Supply-350W, 48VDC

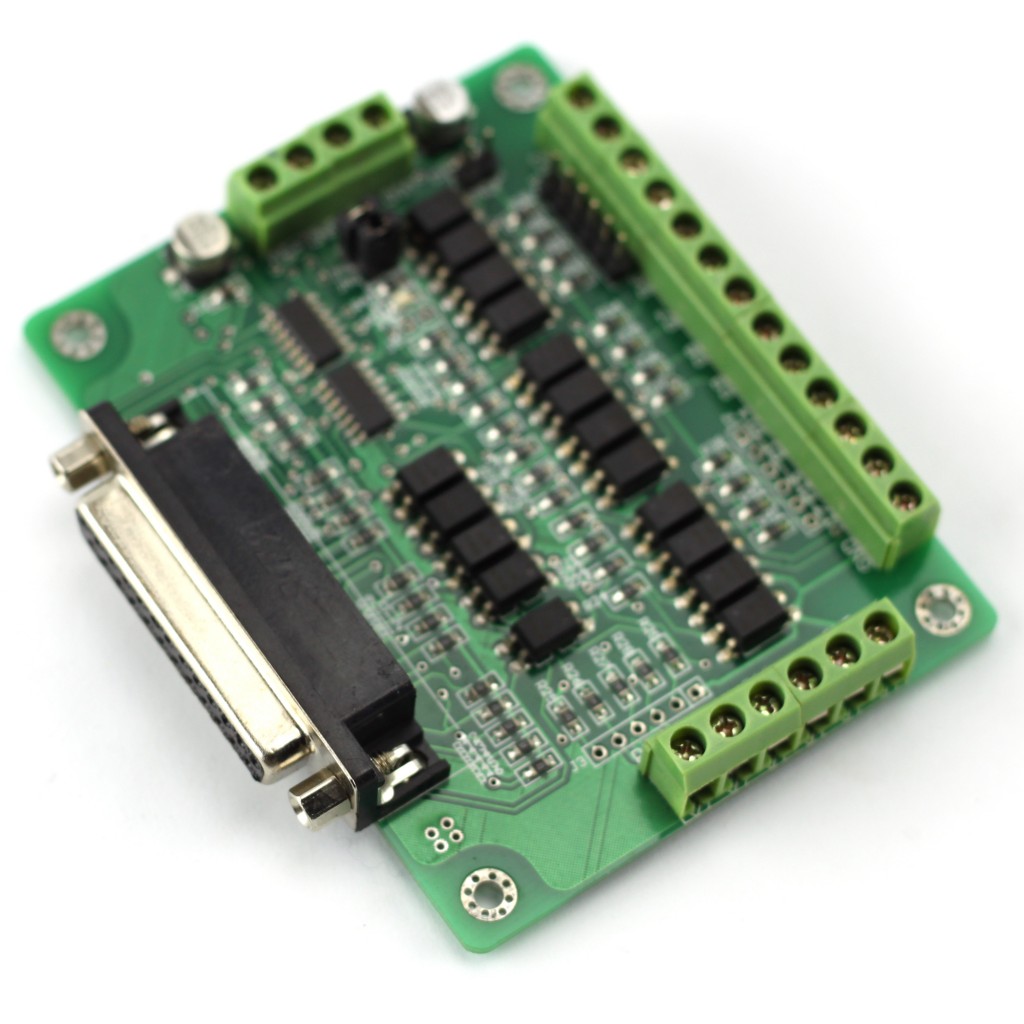

4, Breakout Board

Description:

Built in DB25 male connector.

DB25 Output Pin 1,P2,P3,P4,P5,P6,P7,P8,P9,P14,P16,P17.

1,P2,P3,P4,P5,P6,P7,P8,P9,P14,P16,P17.

DB25 Input Pin: P10,P11,P12,P13,P15.

DB25 GND Pin: P18-P25.

Power supply: +5V DC.

Built in C-class Optical-coupler.

High quality with Surface-mount Tech.

1 PC Breakout Board & 1 Parallel Cable for free offering

j'ai acheté

Voila

http://www.aliexpress.com/item/CNC-kit-3Axis-Nema-34-Stepper-Motor-892OZ-In-85BYGH450D-007B-dual-shaft-Driver-DQ860MA-Power/1359103212.html

[highlight=#ffff80]et je si pas comment le câble , s'il te plait je voudrais comment le câblage (une schémas ) et la configuration de mach3[/highlight]

3 PCS Nema 34 Stepper Motor with 892oz-in (6.3N.m for bipolar connection)holding torque,dual shaft

3 PCS Stepper Motor Driver DQ860MA,24-80VDC,7.8A Peak Current,256 Microstep replacing MD882,

1 PCS 350W, 48VDC,7.3A, Power Supply.

1, Stepper Motor

Technical Specifications

Part No.: 85BYGH450D-007B (Dual Shaft)

Frame Size: NEMA34

Step Angle: 1.8 degree

Voltage: 6.4V

Current: 2.0A/phase

Resistance: 3.2 Ohm/phase

Inductance: 15 mH/phase

Holding torque: 6.16N.m 880oz-in (with Bipolar Connecting)

Rotor inertia: 3600g-cm2

Number of wire leads: 8

Weight: 3 kg

Length: 94mm

2, Stepper Motor Driver DQ860MA

Introduction:

DQ860MA is a type of two-phase hybrid stepping motor driver, The drive voltage of which is from 24VDC to 80VDC. It is designed for use with 2-phase hybrid stepper motor of all kinds with 57mm to 86mm outside diameter and less than 7.8A phase current. This circuit that it adopts is smiliar to the circuit of servo control which enables the motor run smoothly almost without noise and vibration. Hording torque when DQ860MA run under high speed is also significantly higher than the other two-phase driver, what’s more, the positioning accuracy is also higher. It is widely used in middle and big size numerical control devices such as curving machine, CNC machine, and computer embroider machine, packing machines and so on.

Features:

High performance, low price

Average current control, 2-phase sinusoidal output current drive

Supply voltage from 24VDC to 80VDC

Opto-isolated signal I/O

Overvoltage, under voltage, overcorrect, phase short circuit protection

15 channels subdivision and automatic idle-current reduction

8 channels output phase current setting

Offline command input terminal

Motor torque is related with speed, but not related with step/revolution

High start speed

High hording torque under high speed

3, Power Supply-350W, 48VDC

4, Breakout Board

Description:

Built in DB25 male connector.

DB25 Output Pin

DB25 Input Pin: P10,P11,P12,P13,P15.

DB25 GND Pin: P18-P25.

Power supply: +5V DC.

Built in C-class Optical-coupler.

High quality with Surface-mount Tech.

1 PC Breakout Board & 1 Parallel Cable for free offering

Dernière édition par un modérateur: